Chemical Engineering

In chemical engineering, the efficient use of chemistry, physics, mathematics, and economics is the key to a successful design of complex and large-scale production chains. Detailed process knowledge can unlock hidden potentials in an existing production chain or plant design.

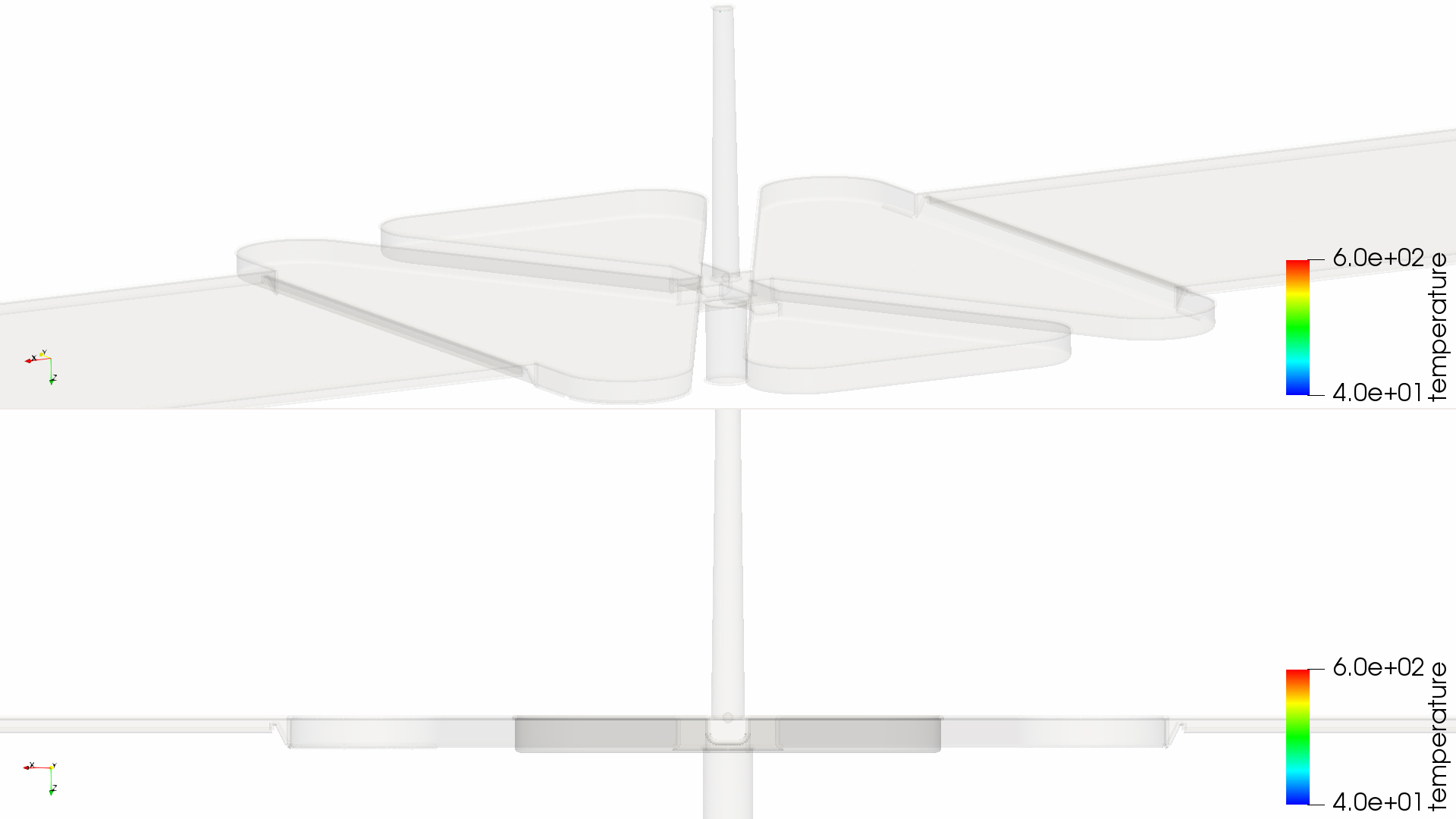

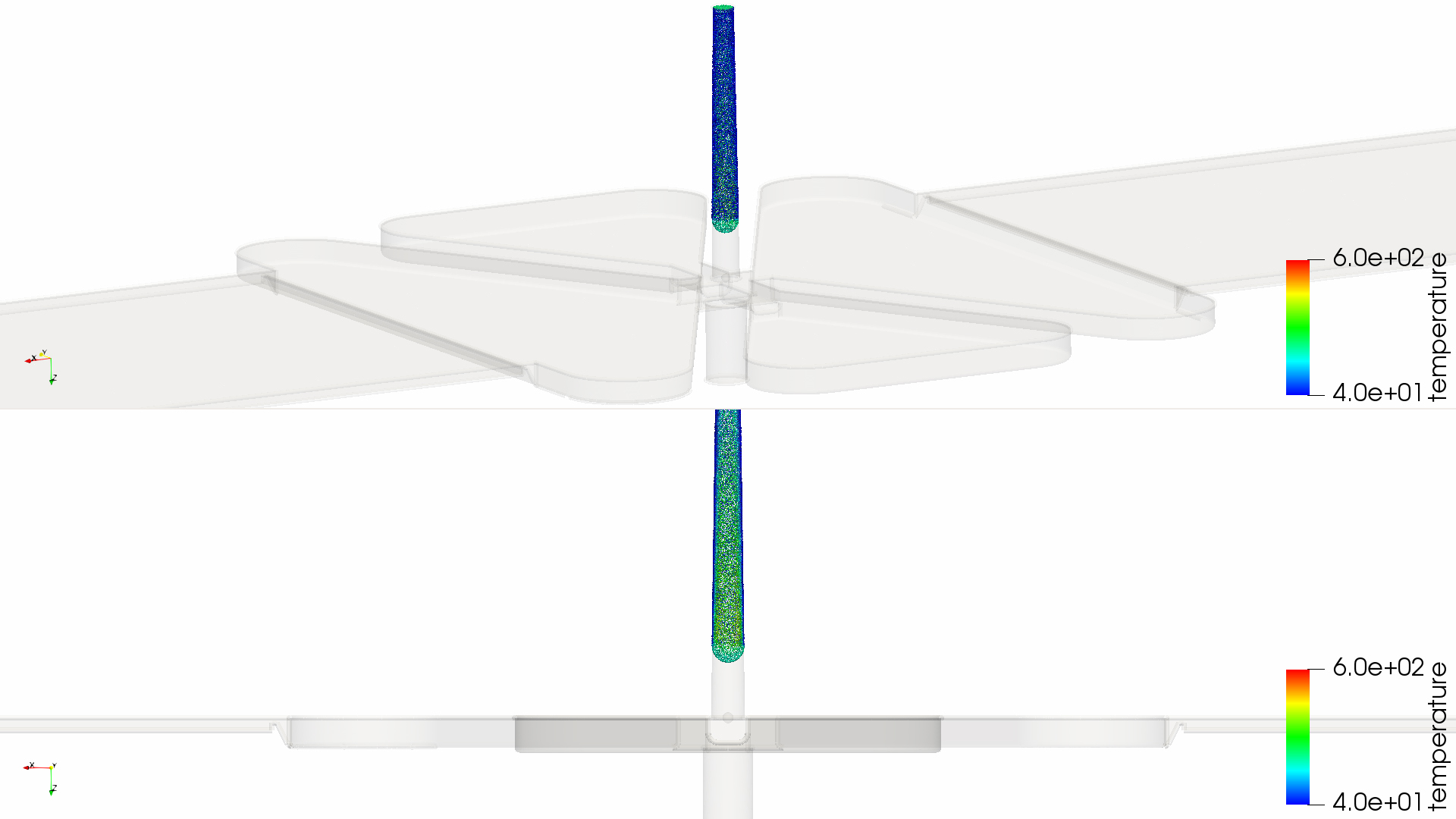

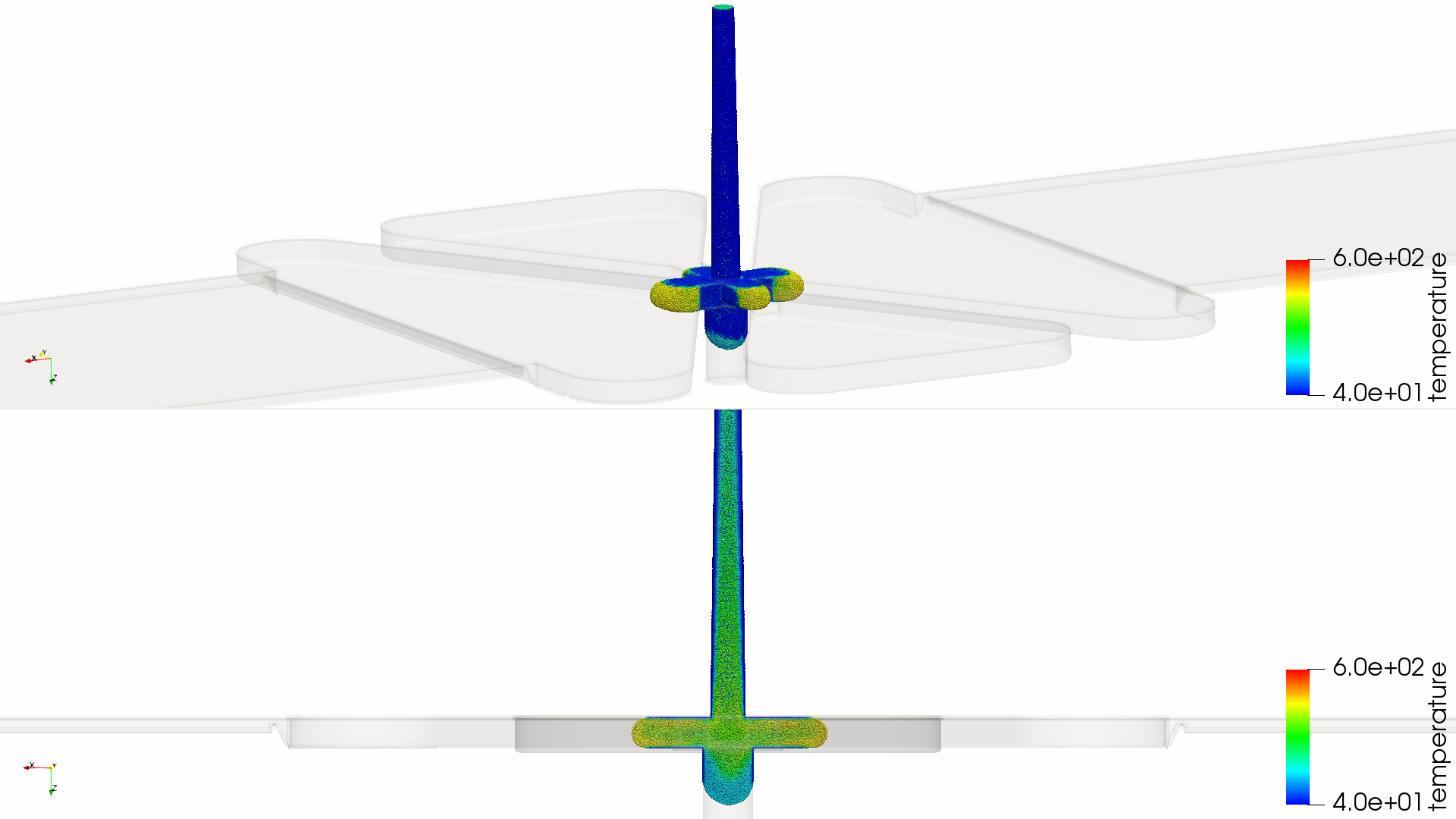

Virtual modeling of individual processes can be performed at early planning stages. It yields design proposals or optimized process parameters in an existing production chain.

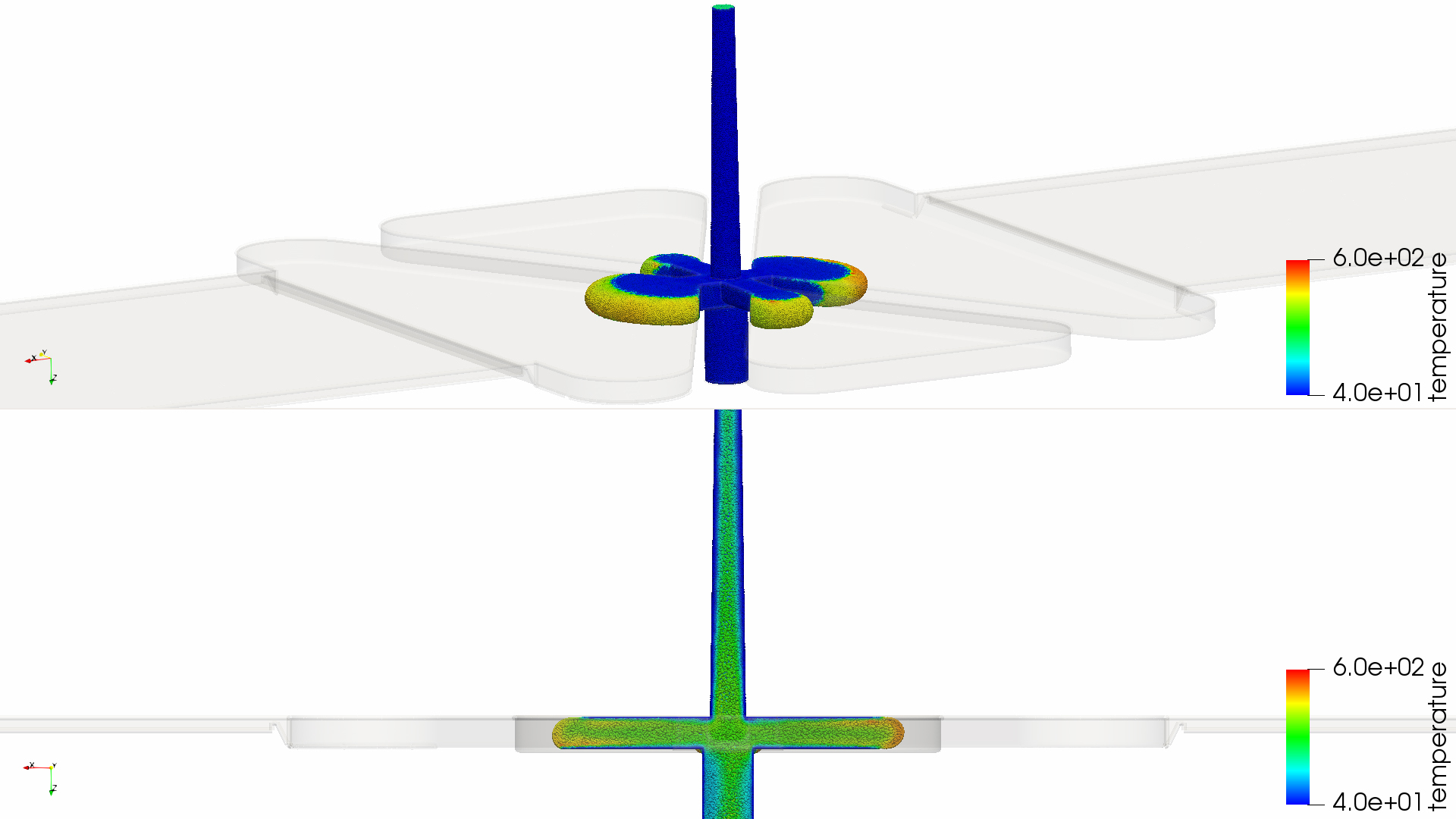

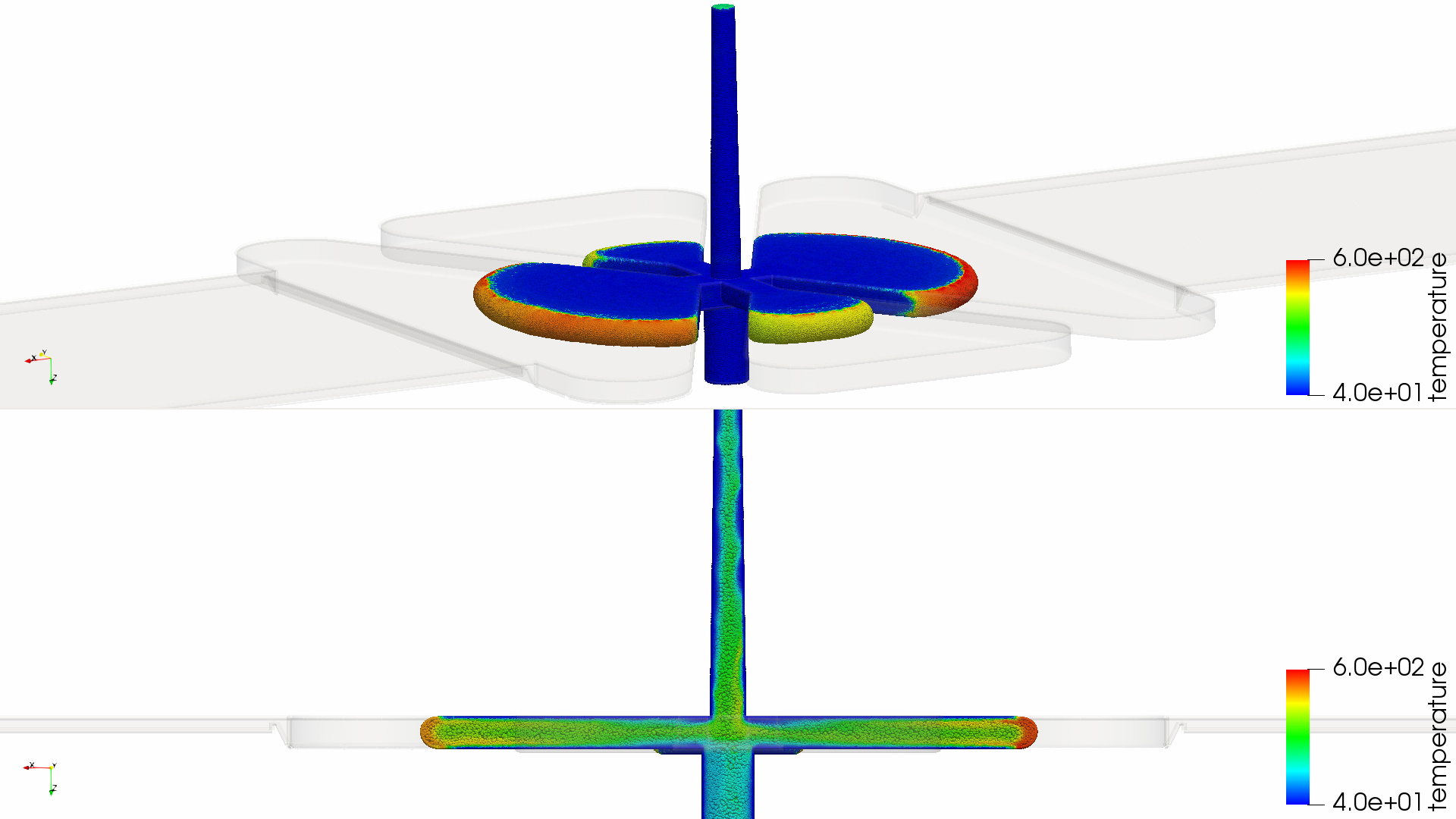

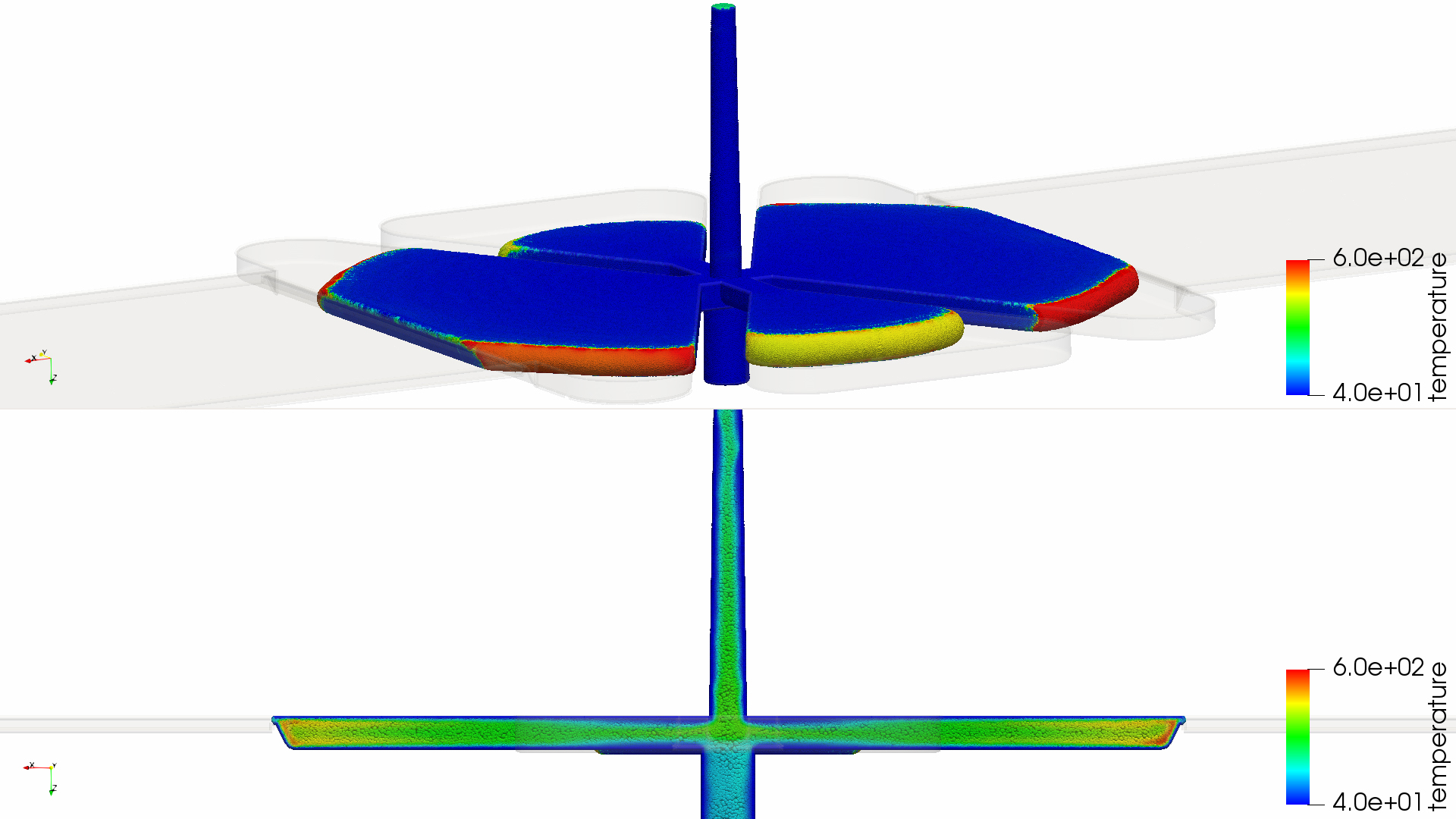

With MESHFREE, we offer a virtualization tool able to generate detailed knowledge of individual process steps governed by fluid dynamical and thermo-dynamical phenomena through simulation. Also, Non-Newtonian fluids can be considered. Possible applications include:

- Static and dynamic mixing and stirring processes

- Mold filling processes – possibly with expansion of the considered fluids

Simulate with complex geometries and complex physics

Simulate with complex geometries and complex physics